Whew…now that was a good day’s work. Since the weather was nice, my primary goal was to finish prepping the flap components so I could shoot primer. First order of business was to countersink the bottom spar flange where it mated with the hinge half. But first I wanted to figure out the final length of the hinge half (I knew it wasn’t the full length of the spar), which in turn meant doing a rough fit-up on the wing. The flap is positioned 1/4” from the aileron…so now I needed to be sure the aileron was located correctly before doing anything else. I’d followed the plans for the washer stickups at the hinges, but an examination of the wingtip showed that the outboard edge of the aileron wasn’t aligned with the outboard edge of the top skin. Was that intentional or not? A look at the plans seemed to show this misalignment, and to make double sure, I pulled down a wingtip and held it in place to get a look at how everything lined up.

So finally, I was convinced that it was OK to position the flap off the aileron. I made a 1/4” spacer out of two paint stirrers glued together, lined the flap spar and aileron up, and marked three hinge tooth segments to remove from the inboard end. The other flap spar came out the same way (as it should have), and finally I was able to proceed with the countersinking. Then I dimpled all the other spar flange holes along with the ribs.

I was taking a final look at the inboard reinforcement pieces when I noticed a small imperfection right beside one of the rivet holes. At first I tried buffing it out with the scotchbrite wheel, but it seemed to be surprisingly deep. Eventually I realized what it was – a center punch mark. Apparently when I drilled this hole, the drill bit wandered far enough that the original punch mark was still there:

Probing it with a punch, I verified it was quite deep. In any other area, I’d remove some material until the mark was gone, but here, that would mean impinging on the rivet hole, which I wasn’t comfortable doing. And I didn’t want to just leave the mark either. Fortunately, there was enough of the original angle material left to just make a replacement, so that was what I did. All in all, it was pretty straightforward, only cost me about half an hour or so.

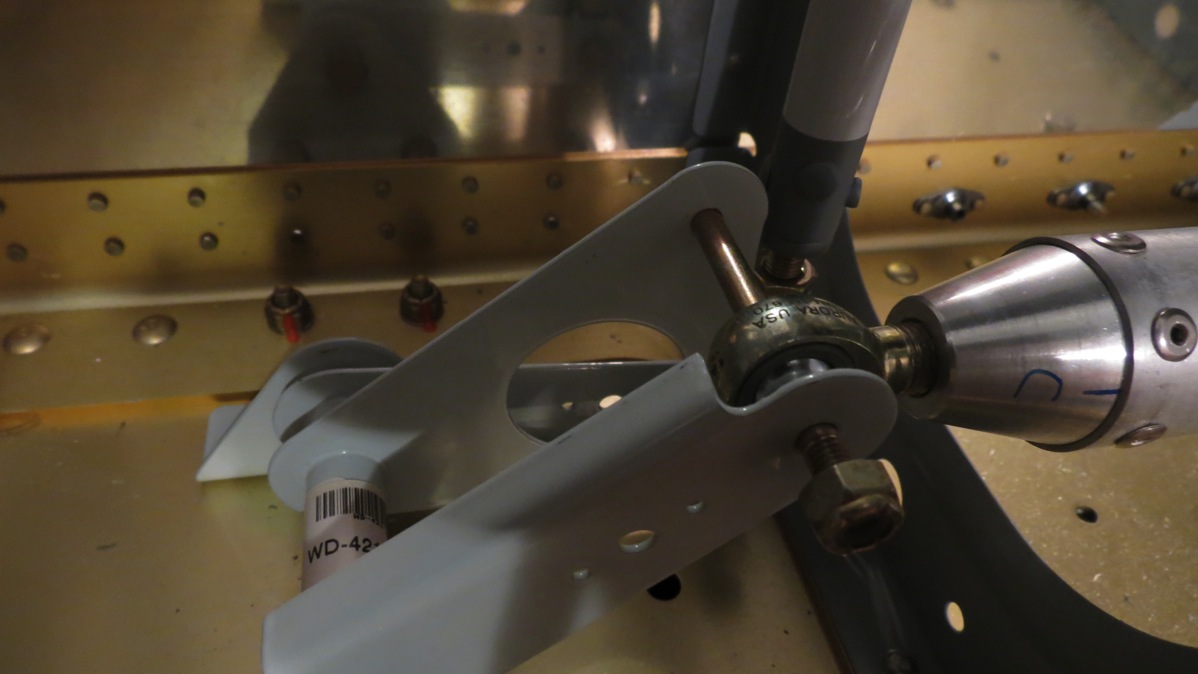

Finally, I was able to go clean all my parts. In addition to the flap parts, I cleaned the aileron pushrods, which also needed a coat of primer. I worked up a fun bit of redneck engineering to hold the pushrods for priming. Basically I just stuck a 3/16” dowel in each end, then stuck the dowels through holes in the saw horses. This gave me access to shot the whole pushrod without it resting on anything:

After a whole lot of time in the driveway, I had a nice bunch of primed ribs:

Next I figured I’d start deburring the flap skins, so I started pulling off the blue plastic. I’d read before that it was necessary to be careful while doing this, lest you accidentally bend your piece. Well, I think I was probably daydreaming about how careful I needed to be when I did this:

Urgh. That’s the little bend at the very leading edge of the top skin, resulting in a slight bow to the curved portion which fits under the trailing edge of the top main wing skin. Thankfully, fixing it wasn’t that difficult. I clecoed the spar in place to apply some straightening force to the skin, then went to work on the creased area with a hammer and wood block, along with some hand seamers to apply some targeted force. The end result looks practically good as new:

Finally, I went to work deburring the rivet holes in the skins. That seemed like a good stopping point for a good day’s work, so I quit. That just leaves deburring the edges of the flap skins and dimpling them, and then it’ll be time to do some riveting. And then I’ll be closer to getting rolling on the fuselage!