It’s happened again…me getting a little carried away with my goals. I pretty much figured out by the middle of last week that this wasn’t going to be a tank-sealing weekend, but I was still sort of trying to go for it. Then, at some point yesterday, I just decided to let go and enjoy my long weekend. Yesterday I slept in, we took the dogs to the beach, and watched a movie in the evening. Today we got up super early to watch the MotoGP race at Silverstone, then I slept in some more.

ObviouslyI did get out to the garage, or I wouldn’t be writing this. I set about repeating the work from Friday, reaming out the screw holes and hypnotizing myself by staring closely at shiny aluminum. And now I have two fully-deburred skins, ready for dimpling.

I didn’t really want to get into dealing with the ribs, so instead I decided to do a small trial run with the sealant. I broke out one of the cans and mixed up a small batch, with the intention of doing nothing but spreading someone a piece of cardboard so I could see how the stuff cured. It turned out to be an educational process. The sealant itself is extremely thick, like peanut butter, and it sticks to everything. Scooping a controlled quantity into a plastic cup was quite a challenge. The activator is much better though. Stirring the two together thoroughly in the cup was also difficult, and I found it impossible to not leave streaks of unmixed stuff along the walls of the cup. Clearly this method of mixing is not going to do.

The stuff I did get mixed OK, I put into a cheap plastic food storage bag. Instead of buying an expensive sealant application gun, I figured I’d try using a bag with the corner cut off to make nice beads. This part worked fairly well, although I cut the hole kind of big and made a rather large bead on the cardboard.

Afterwards, I did some research at VAF and saw recommendations for using a piece of tile as a mixing surface. I was skeptical of this approach, given how tough the cured sealant is supposed to be, but apparently it can be easily cleaned off the tile with a razor. So I guess I’ll run to Home Depot maybe tomorrow and see about getting a piece of scrap tile. Mixing on that should work much better, I think.

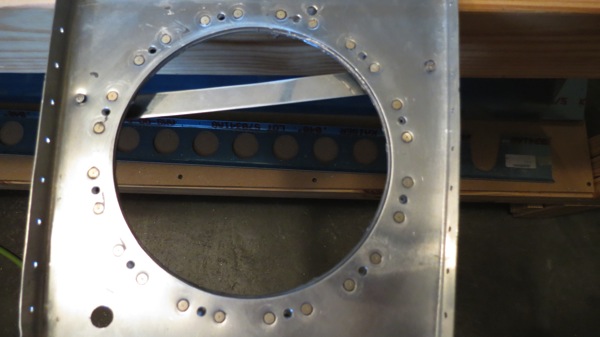

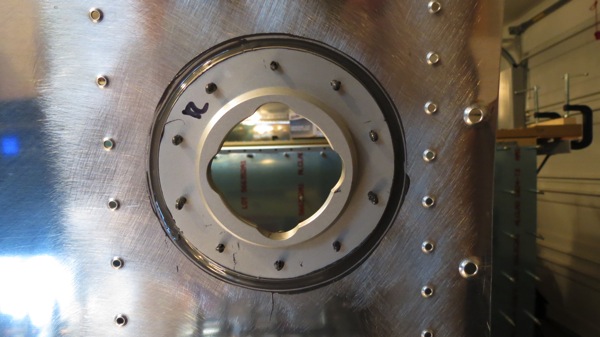

I may shoot for installing the access plate rings on the end ribs in the next few days as my first sealing adventure. That’ll make for a nice small-scale introduction to working with this stuff.