Well, tonight is a shining example of what I’m going to call “cascading dependencies.” My initial plan tonight was to start by just finishing the few remaining steps in the current construction manual section, then go back to the incomplete pages from earlier and see where I needed to pick up there. Literally the two remaining steps in this section were to rivet some nutplates to the quadrant cover and then install the quadrant in place.

But here’s where it gets fun. Way back when I was working on the quadrant, I’d decided to go with a fixed-pitch prop, and all my work had revolved around that, from working out the linkage to the rear throttle to fabricating a custom throttle cover plate. Since then, I’ve decided I want a constant speed prop after all, so I knew at some point I’d have to revisit all those things, and tonight was that night.

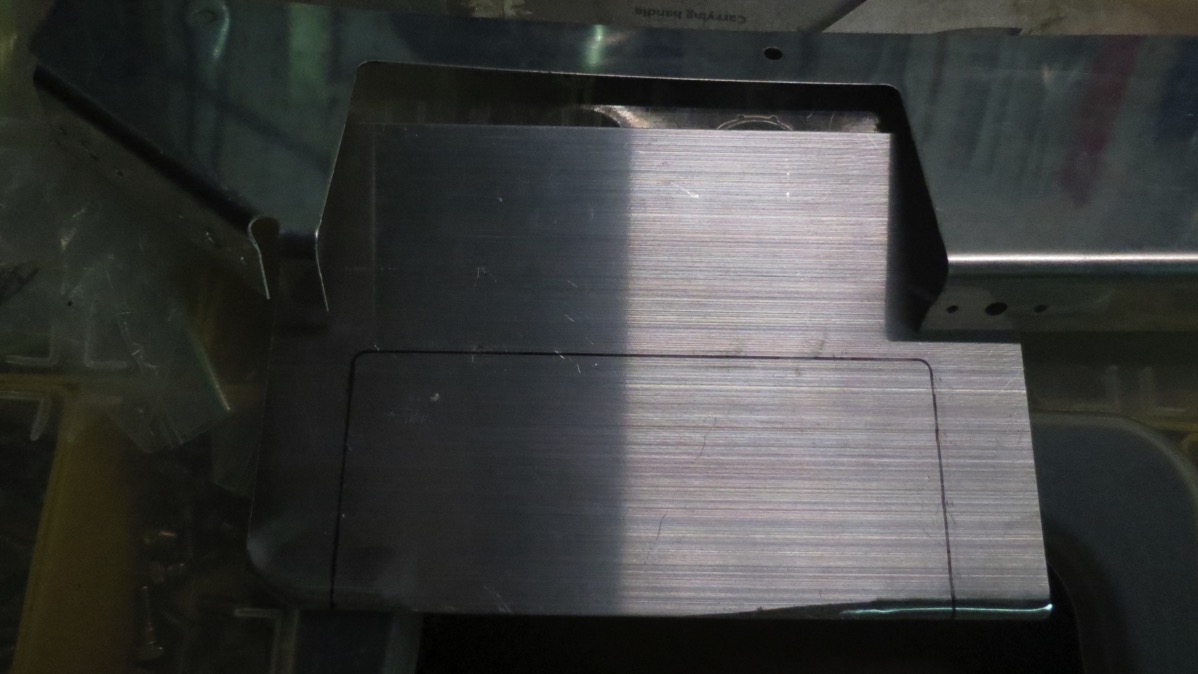

So I swapped the throttle quadrants out on their mount, then looked at modifying my custom cover plate. Except I discovered a crack in that plate emanating from a screw hole. Sort of randomly I decided to go dig up the factory cover plate (whose opening is too large for the smaller two-lever quadrant), and whaddya know, the opening is the perfect size for the three-lever quadrant. Nice easy solution to that issue.

The next fun was/will be reworking the linkage to the rear throttle. Since the three-lever quadrant is obviously wider, it places the forward throttle lever bit further outboard (I haven’t measured it exactly, but I think it’s something like 1/8”). That, in turn, means that the holes I carefully cut through the center section bulkheads and other parts need to be expanded outboard. I got as far as temporarily mounting both throttle quadrants and routing the linkage, just to begin evaluating where and how I’ll need to trim.

The good news is that I don’t think I’ll need to remove that much material, and also there’s plenty of room to expand the passthrough holes as well. The bad news is that it’s going to be harder to work with these holes than last time – when I did this before, the side skins weren’t on and I had great access. Now I’ll have to be leaning into the fuselage the whole time, though that’s made easier by the fuselage rotisserie setup. But I’m definitely remembering how much time I spent on trial-and-error the first time around with this. The work isn’t that bad, but having to repeatedly install and remove the quadrants and linked is a bit of a pain.

So next time I’ll pick up with this bit of fun. I should be able to get this done in one solid work session, and then I can finally rivet those nutplates and get a little closer to hanging the empennage.

Oh, and that raises another point – this is probably a good time for me to decide whether or not I’m going to preemptively do the SB 14-01-31 reinforcement work. Technically the service bulletin doesn’t require the reinforcement be done until/unless cracks are observed in the spar, and I have to say the work doesn’t look like a lot of fun to do. On the other hand, it’s not going to be any more fun ten years into the airplane’s lifetime either. And to be honest, at this point if I massively ruin something, I’d probably just build a new horizontal stab. It wouldn’t be the end of the world.

Basically it’s just a matter of deciding whether I want to bet that I’ll never actually develop the cracking. It’s been a while since I read up on the SB info, but I seem to recall it was more common on some of the older RV-7 kits that didn’t have precut relief notched in this area. I dunno, I’ve just gotta go do some reading again.