Yes, shenanigans. It’s the most appropriate word, I think.

The overall goal was to apply filler around the oil door opening so I could get a nice paint gap as well as have the door be flush with the cowl around it. The first step to this was to basically sand off the factory-molded lip around the oil door flange, so I could build it back up. Then there was the really fun part – figuring out a way to add some material to the door itself so that when I laid up the micro, I’d get a reasonably usable starting point for the gap.

First, I tried just using layers of electrical tape, kind of like I did for the cowl pin covers. Problem was, I wanted more layers than I used for the covers, and trying to lay on a bunch of tape while still keeping the edges tight, and invariably, after about three layers I’d get a wrinkle. Then I made a brief attempt to use self-fusing tape, which is thicker, but that just didn’t go well at all.

Finally, I tried using some edge molding I had laying around. This is stuff you might stick inside a lightening hole to avoid chafing, and I thought I could apply it around the door. At first, it didn’t really want to lie flat, but with some strategic electrical tape, it seemed OK:

I followed this up with another layer of electrical tape around the perimeter, and checked the fit against the sanded-out door cutout:

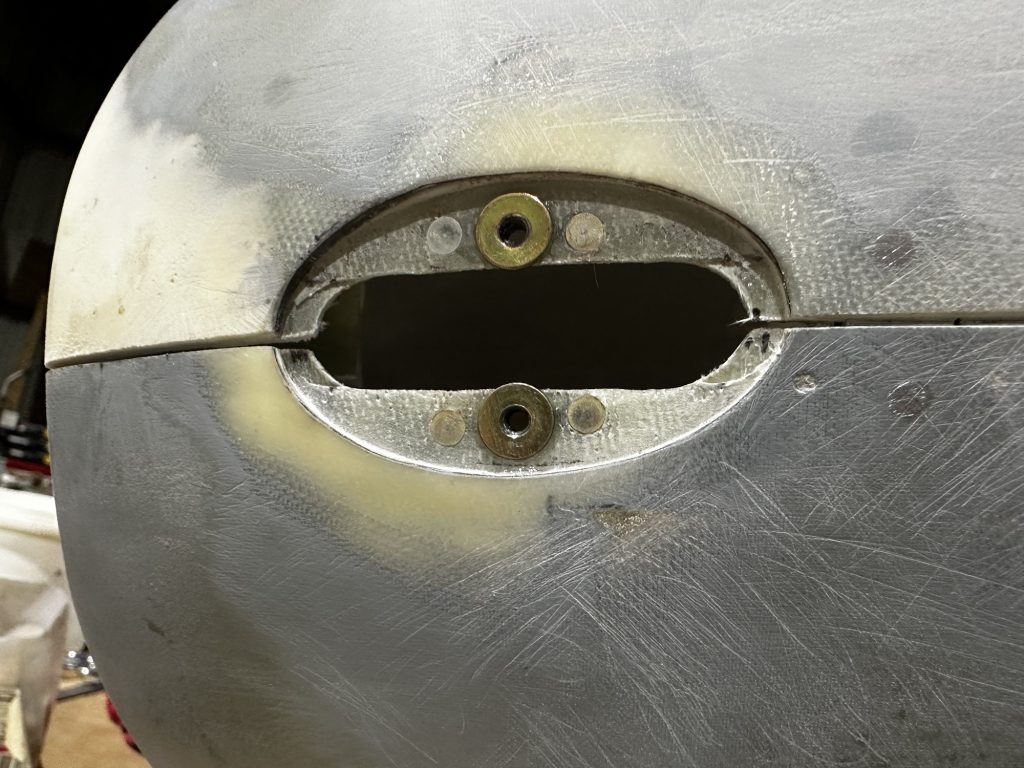

Then it was time to glop on the micro, reinstall the door to squeeze out the excess, and build up as needed around the perimeter:

This ended up being way more micro than I needed, so the next day I had a whole lot of sanding to do to get back down to the proper contour. As I worked that down, I could see that the edge molding apparently hadn’t been flush all around – there was one particular spot where it must have popped out a bit, and so I had an excessive gap. I went ahead and sanded everything down, then worked on fine-tuning the gap, hoping I could make it less obvious, but in the end I wasn’t happy with the result. The annoying spot is at the bottom right of this photo:

So…I sanded all that micro off and started over again. This time I made another attempt at just wrapping with electrical tape, but by being VERY careful I was able to get the whole thing done with no wrinkles. Once again, I glopped on the micro, added the door, and built up as needed:

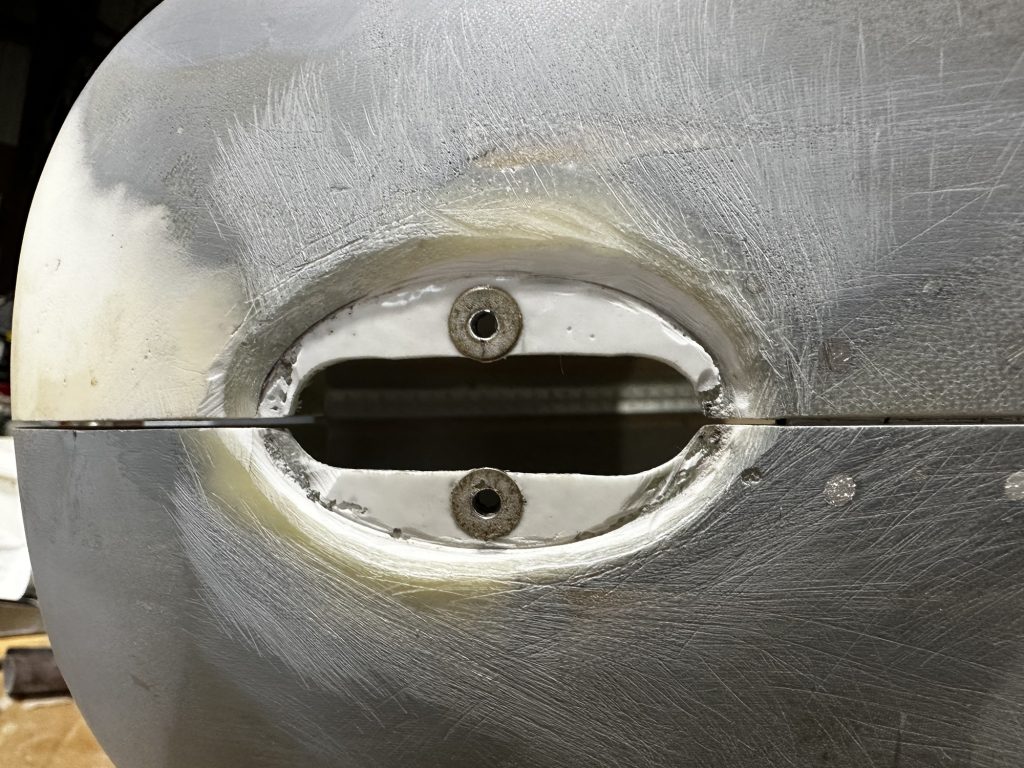

This time, the results were better. It was a little annoying to go through thee exact same contour sanding operation again (at least I used less micro this time), but after it was all said and done, things were looking pretty decent, though I think I’ll still end up doing more fine-tuning of the gap here when I finish the cowl as a whole:

So now I suppose it’s back to the hinge and latch…