So…what I’ve really been wanting to work on has been the firewall passthroughs for electrical stuff. Specifically, I wanted to get the fitting installed on the right side of the firewall so I could pull the wiring bundle through and start working on routing the ignition wiring back into the cabin.

When I looked at the fittings I bought, and read the instructions, I saw they specified #6 stainless screws for attachment, or stainless pop rivets. Given how tight things are inside the cabin where these fittings would attach, I really wanted to go the rivet route, and so I spent way too much time trying to find any 9/64” stainless pop rivets, to no avail. I also considered sizing up to 5/32” – a much more common size – but all the rivets I could find had too much grip length.

So I resigned myself to the screws. Before ordering from Spruce, I worked up a few other parts I needed, in a vain attempt to save on shipping. Critically, when it came time to place the order, I wasn’t sure the right screw length. But I thought to myself, “these are only going through two thin pieces of stainless, the shortest length is probably right.”

You can probably guess where this is headed. I got the attach holes for the fitting drilled into the firewall, grabbed one of my new screws, and…oh my, that’s way too short. The screws aren’t even long enough to get full engagement from a lock nut with no material in between, much less my two pieces of stainless and a washer.

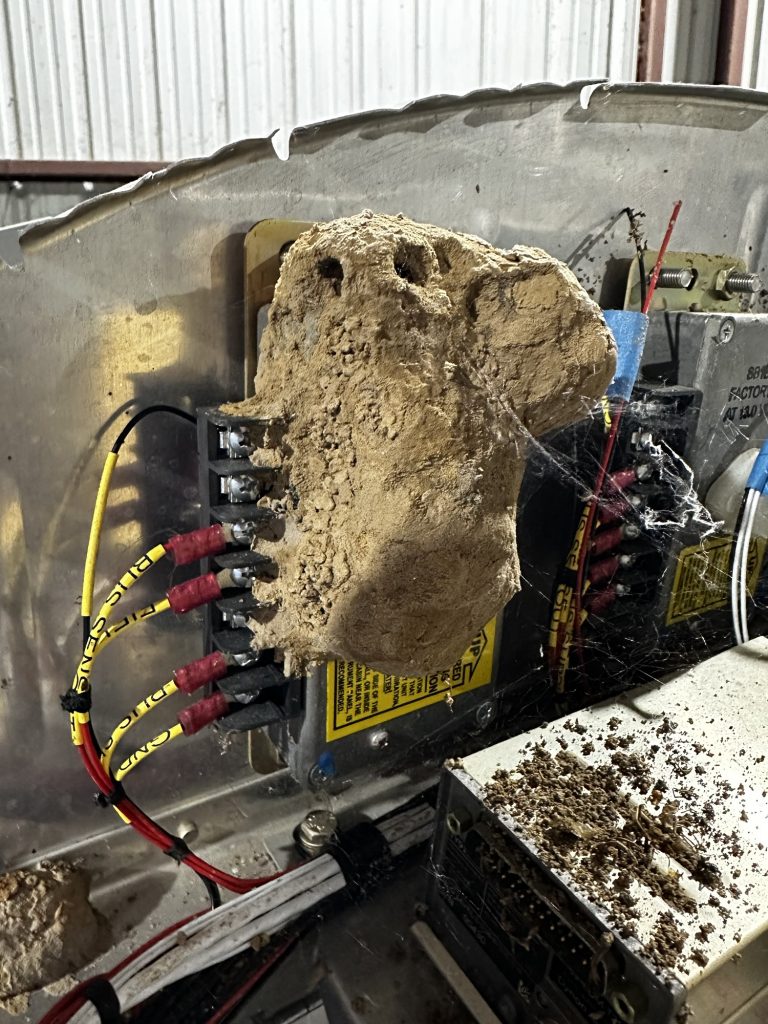

Welp, time to move on to something else until I can grit my teeth and either order from Spruce again or just buy some hardware screws locally. Fortunately, I had another task I’d been thinking on – how to brace the baffles at the back of the engine. I’ve mentioned this a bit before – the baffle kit comes with a brace that attaches to the case bolts and holds the baffles in place, but I can’t use that because my ignition coil pack will be mounted there.

I’d ginned up a few possible ideas, none of which I liked much, but then a couple weeks ago I saw a photo with a brilliant solution. Instead of bracing from the front, using the case bolts, this person was bracing from the rear, using the top two bolts on the accessory case. The brace itself looked relatively simple to fabricate, and I’ve got some scrap .063 stock lying around that would be perfect for this.

The main challenge for fabricating and fitting this would be the work space – on the back of the engine, near the engine mount, and up at about my shoulder level with the plane on the gear. Visible here – with that annoying mount in the foreground – are the two bolts that will anchor the brace:

The first fun part if figuring out the spacing of those bolt holes, since obviously the brace has to be drilled to match them. Trying to measure this with all the stuff around was going to be a real pain, but after some more thinking, I came up with an idea: a simple shop-made measuring tool. I cut a couple strips of scrap, drilled 1/4” holes in one end of each, and a 1/8” hole in the other end. A cleco through the smaller hole acted as a pivot, and a third 1/8” hole in one piece anchored a final piece of stock. That final piece made a sort of “A” shape, allowing the tongs to be fixed in a relative position.

Then I just bolted the ends to the case, clamped my crossbar in place, and I had a template for those two holes:

Easy to measure this over on the bench, and…very nice of Lycoming to make the bolt hole spacing exactly three inches:

Using that measurement, I started working on a cardboard template. First step was to just locate the bolt holes and lay out the surrounding shape to clear the accessory case, then I did a trial fit to make sure that my bolt hole spacing and the surrounding shape would work out. Seems good to me:

That was the end of the night’s work. Next will be the more-fun task of roughly locating the two bends I’ll need to get this piece touching the baffle, and then will come the real fun of starting to replicate this thing in aluminum and getting it to fit right.