So after examining my options for dealing with the linkage mount hole location – in particular taking a close look at potential edge distance issues on the center section bulkheads – I decided that I could proceed by simply enlarging the passthrough holes in the bulkheads. I carefully drew lines on each bulkhead so I’d know where my edge distance limits were, then went to work enlarging the holes.

Here’s the enlarged forward hole. The vertical edge distance guide line can be seen, along with a horizontal line showing how far downward I wanted to enlarge the hole:

Meanwhile, I disassembled both throttles (…again…) and used the rear throttle arm to mark the hole location on the forward arm. Blue marker doesn’t show up very well on the black arm, so I added some blue masking tape around the perimeter of the hole location to provide a better visual guide. Then I reassembled both throttles (…again…) and mounted them both in place (…again…).

Getting there:

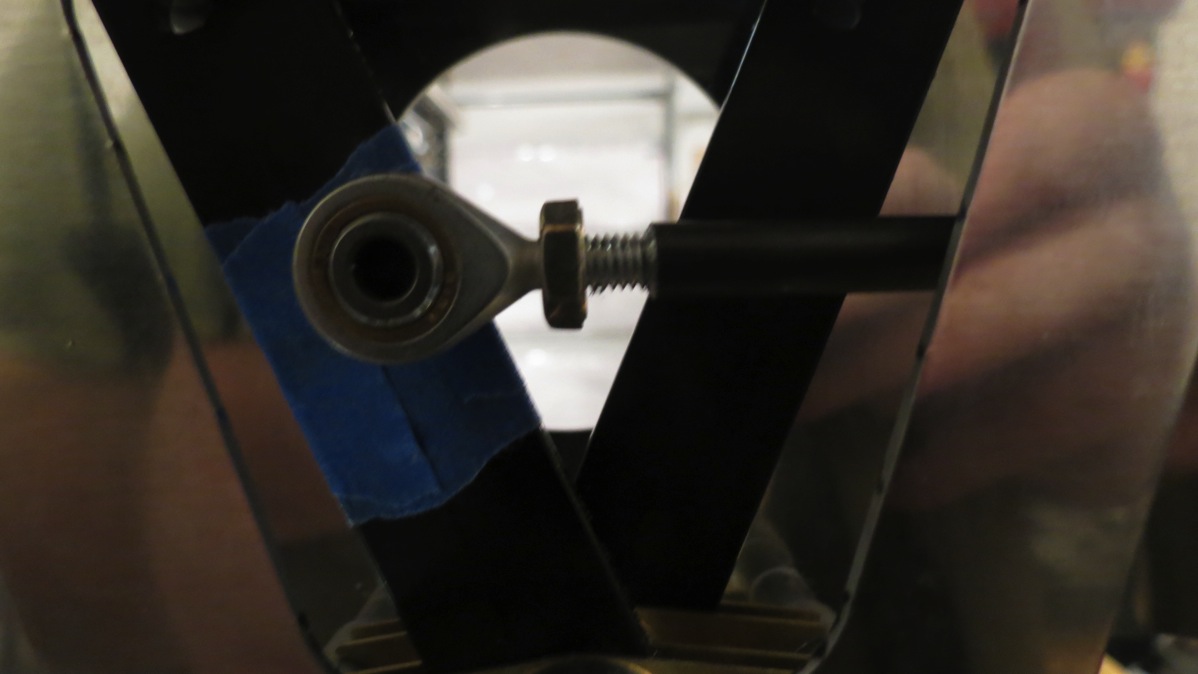

At this point, the linkage was interfering with the rounded “corners” of passthrough holes, not the absolute bottom, so after removing both throttles (…again…), I filed the holes outward and downward to provide some more clearance. Then I reinstalled both throttles (…again…). Even closer this time (sorry, no photo), but now there’s a new issue. This is the current interference point, preventing the linkage from going lower:

To get more clearance here, I’d have to file the hole basically straight towards the rivet hole, but I’m not comfortable removing any more material in this area. Both passthrough holes have ample clearance on the outboard side of the linkage though, so I think what I’ll do to address this issue is move the forward throttle outboard a bit. That should move any potential clearance issues to the outboard side of the passthrough holes, where I’m much more comfortable removing material.

But that requires removing and disassembling the throttles (…again…), and I’ve had enough for one night.